Features

Technical Parameter

|

Item |

Product Name |

Model |

|

1 |

Paper straw making machine(high speed) |

GDZGJ-30 (9blades) |

|

2 |

Paper straw bending machine |

GD-Be450 |

|

3 |

Dryer for paper straw |

GD-ED |

|

4 |

U shape straw packing machine with bevel cutting function |

GD-P500 |

|

5 |

Lifter conveyor |

GD-PSF |

|

6 |

Automatic vision inspection machine |

GD-W01 |

|

7 |

Tetra-pack straws mega-boxing machine |

GD-LC |

High speed paper straw machine(5 servo motors)

Winding/spiraling different layers paper strip into paper tube with glue.

Multi-cutting knife system, by servo tracking, cut paper tube into small piece of paper drinking straws.

Material: food grade white craft paper and food grade glue.

Sub-raw material: may need oil for lubrication and cooling. White mineral oil.

Standard electric power: 380V/ 3phase/ 50Hz, could change by special requirement, like 60Hz or 220V/ 3 phase.

Electric consumption: Rated power, 6.15KW/h

FLA( Full load amp): 13.5A

Capacity

How many pieces straw per minute. For example: 80m/min, making 6*197mm straws. Consider some waste, we use 200mm for calculating.

80*1000/200=400 pcs/minute.

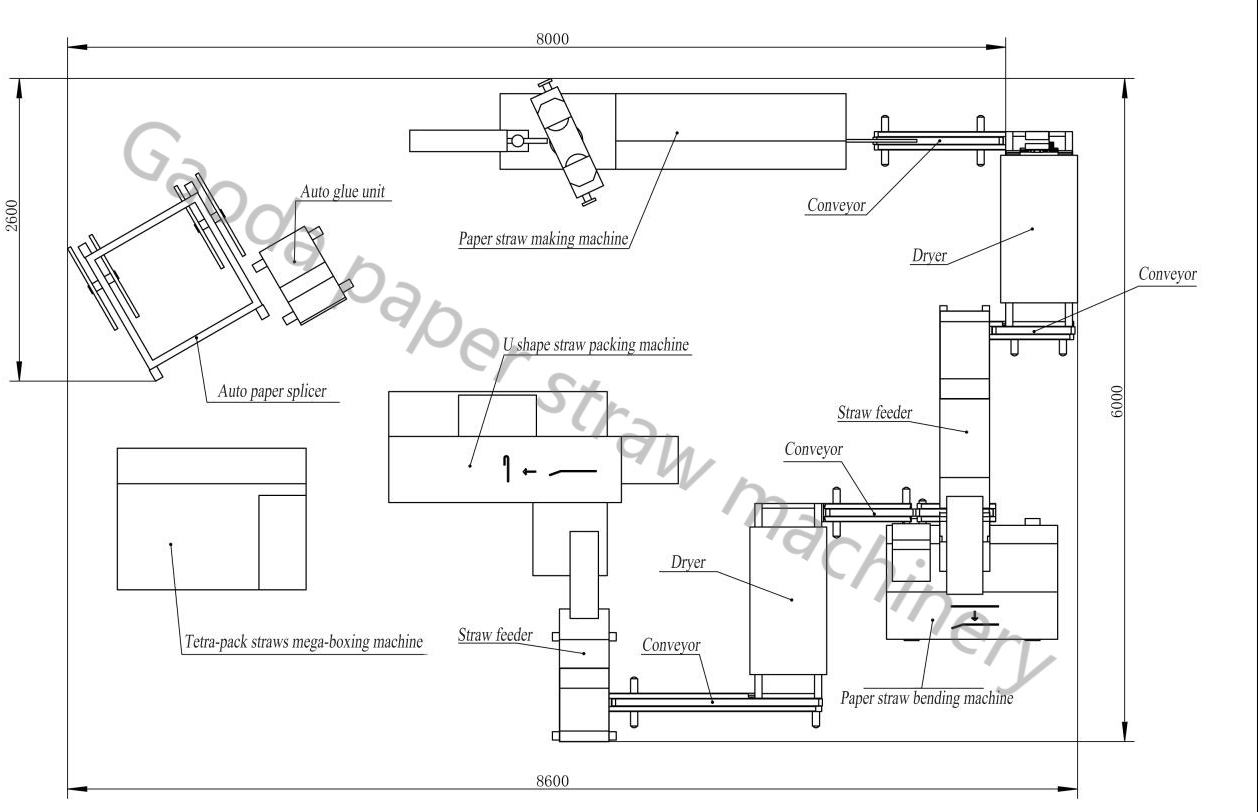

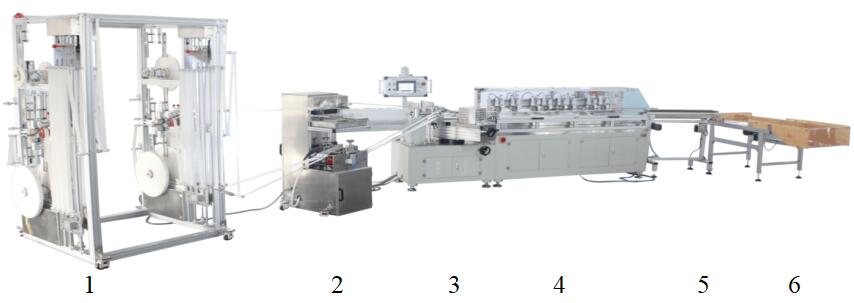

Total machine includes 6 parts: from left to right side

- Paper roll hanging bracket, 4 layers, auto connecting/splicing;

- Glue station, stainless steel, glue auto feeding;

- Winding and control mechanism;

- Muti-cutting system, 8 cutting knives with dust & protecting cover;

- Conveyor;

- Collector.

Advantage of GDM-30

- Higher Speed,max 120m/min input, 95m/min out put.

- 9 cutting-knife system, new structure of cutting cylinder. Easier to adjust air cylinder up and down when making different diameter paper straws.

- 5 sets servo motor for spiraling roller, cutting system moving left & right, supporting roller and cutting knifes.

- Auto paper roll connecting function hanging bracket, auto splicer, 4 layers. Other brand paper straw making machine paper roll hanging bracket is only 3 layers.

- Auto feeding function glue station.

- Auto lubrication grease feeding system for cutting system.

- Main electric parts choose famous brand, Schneider. Like main servo motor, servo motor driver, frequency converter, touch screen .

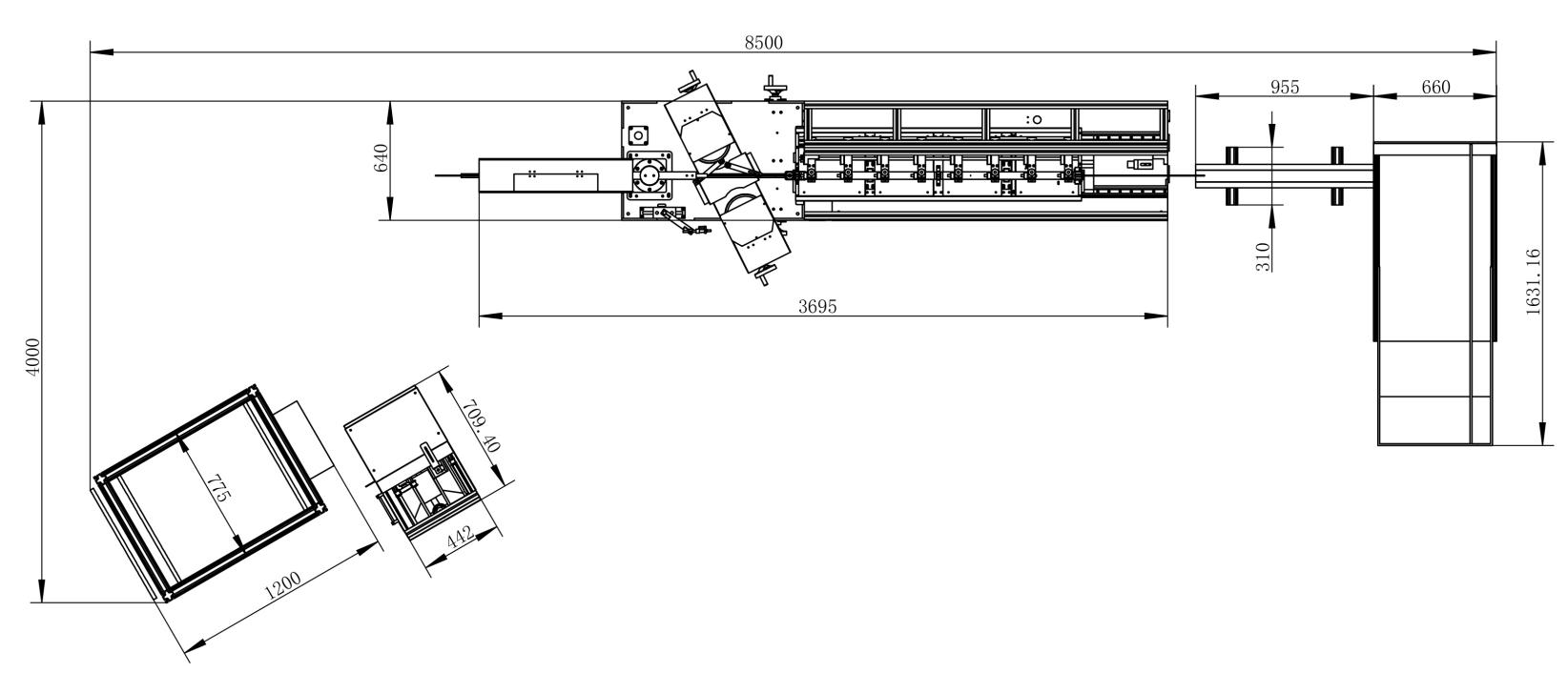

Overall size

Different unit dimension

|

Unit Name |

Dimension (mm) |

Unit Name |

Dimension (mm) |

|

Winding & control unit |

1720*1050*1680 |

glue station |

670*720*1430 |

|

Multi-cutting system |

1950*650*1450 |

Conveyor |

1200*400*1050 |

|

Paper roller bracket |

1120*1300*2050 |

Straw Collector |

1650*520*1080 |

Specification and Parameter

|

Model number |

100M high speed paper straw making machine (GDZGJ-20) |

||

|

Technical parameter |

Control system |

||

|

Layer of paper |

3-4 layers |

PLC controller |

Schneider |

|

Max. diameter |

12mm |

Human machine interface |

Schneider |

|

Min. inner diameter |

5mm |

Program version |

GD-XJ2.0 |

|

Max. thickness |

1mm |

Servo system |

Schneider |

|

Min. thickness |

0.2mm |

Performer |

Schneider |

|

Min. length |

70mm |

Max.length(between 2 blades) |

1380mm |

|

Output speed |

3-110m/min |

Signal component |

Omron |

|

Winding system |

2 servo/1 pc belt |

Pneumatic component |

Airtac |

|

Cutting way |

9 knives pneumatic/1 servo |

synchronous control |

Synchronous belt |

|

Glue method |

Double side/single side |

Sync tracking cutting system |

Servo sync tracking system |

|

Lenght control |

encoder |

assemble |

|

|

Operator |

1 person |

Tube rack |

Have |

|

Mandrel fixing |

Screw clamp |

Belt angle adjustment |

Wheel adjustment |

|

Speed control |

servo |

Belt tension adjustment |

Wheel adjustment |

|

Power input |

3P/380V/50HZ |

Paper-break stop function |

have |

|

Dimension |

Glue method |

Schutze glue spray system |

|

|

Machine dimension |

4250×640×1600mm |

Lubrication |

Electric roller |

|

Floor area |

9500×3500×1900mm |

Paper tension control |

Continuous tension control |

|

Wheel diameter |

195mm |

Paper holder |

Automatic paper connecting holder |

|

Wheel height |

100mm |

Belt |

Piece baseband |

|

Max. spin speed |

200r/min |

Totalweight |

1350KGS |

Paper Straw Drying Machine

Product Application

In order to have a better quality for paper straw, it's better to dry nearly one day before packing or wrapping. But sometimes, it's urgently to deliver straws to customers or there's a rainy day, so the dryer machine for paper straws is needed.

Main Features of Paper Straw Dryer Machine

1. Automatic transfer;

2. Energy conservation;

3. Transfer speed and wind speed controllable;

4. Temperature intelligent operation.

|

Model |

Voltage |

Power |

Dimension |

Transporting Speed |

Weight |

|

GD-ED |

380V |

9.6KV |

2300*700*1020mm |

0-10m/min |

120Kg |

Paper straw bending machine

GD-be450 series automatic bendable straw forming machine is the supporting equipment of paper straw machine, which is used to process straight pipes into bendable straw. The whole equipment automatically exits the pipe from input to finished product output, and only needs to manually add the straight pipe blank to the hopper on the upper part of the forming machine.

Main features

1. Stable operation and stepless speed regulation.

2. Automatic counting, designated batch alarm, convenient for manual bagging.

3. It has the function of automatic shutdown in case of failure.

|

Name |

GD-Be450 |

|||

|

Power |

Motor Capacity |

1.5/2.2KW(VFD) |

||

|

|

Power |

380V/3Phase/50Hz(Can customized) |

||

|

Speed |

280-320pcs/min |

|||

|

Paper straw data |

Inner Diameter |

3.8mm |

4.8mm |

5.8mm |

|

|

Length |

165mm-245mm |

200mm-260mm |

200mm-260mm |

|

|

wall thickness |

0.15±0.02 |

0.19±0.02 |

0.19±0.02 |

|

|

Lifting length |

150mm-230mm |

185mm-245mm |

185mm-245mm |

|

|

Length of corrugated upper part |

30mm-50mm(Adjustable) |

||

|

|

Ripple length |

8mm-12mm(Adjustable) |

||

|

Size |

L*W*H 1500mm*1800mm*1600mm |

|||

|

Weight |

1000kgs |

|||

U-shape paper straw packing machine

Product Introduction:

GD-UP500 Tetra Packing machine, it's function is to pack U-shape or straight drinking straws in line, which is used for aseptic-packing beverage like milk and juice. It could finish fold, sharp end cutting and packing at same time.

The beverage company will cut straws into individual package, then stick straws on paper carton and box. (This working process is finished at beverage company, not straw making factory).

The produce process is total automatic. Operator just need put paper straws into the hopper, put on packing materials, then start the machine.

Machine Features:

- Whole process automatically, packing speed controllable, auto stop when there's a fault;

- High production efficiency, one operator, 250-300 pcs/min;

- Bevel (sharp end) cutting controlled by servo motor, ensuring all sharp ends are packed in the same direction. Air absorbing device take waste sharp end materials away

- Automatic counting for how many pcs of paper straws had finished;

- Automatic stop when there is a fault.

- Could u、se packing material like plastic film, or PLA(other biodegradable adhesive) coated paper.

Technical parameters and specification

|

Model |

GD-UP500 |

|

Voltage |

380V/3 phase/ 50hz |

|

Machine size(L*W*H) |

2000x1750x1600mm |

|

Machine weight |

1000kg |

|

Machine Speed |

200-300 pcs/min |

|

Straw inner diameter Straw out diameter |

Inner diameter :3.7 mm; out diameter: 4.5mm 3.7mm,4.5mm Length: 160-170mm,160-170mm Other size are Customization. |

|

Packing method |

Four-sides seal |

|

Packing material |

Material which could be hot sealed. Like BOPP plastic film, or biodegradable adhesive coated paper. |

|

Packing material specification |

Packing material shape: roll; Max roll diameter: 280mm; Max roll width: 180mm; Core diameter of roll: 76mm, 3 inches; Film thickness: like BOPP, 20-30卩m ( 1卩m=0.001mm) |

|

Packing unit(shape) |

Pitch: 22mm, width:100-140mm; |

|

Size of U-shape model

|

Depends on customers design and drawing |

|

Main motor |

2.2 kw/h, brand: SIEMENS BEIDE control by frequency changer, 2.2Kw/h, |

|

Servo motor |

Brand: DELTA,ervo motor: AC, 0.2Kw |

|

Auxiliary motor |

220V, 50/60Hz, 120W, brand: OTG, Shanghai |

|

Magnetic powder brake |

10N.m, DC24V,0.6A, |

|

AC contactor |

Schneider |

|

Pneumatic component |

AIRTAC |

Tetra-pack straws mega-boxing machine

GD-PSF Zig-Zag Mega carton folder is an auxiliary equipment of the JY033 U-shape drinking straw packing machine and JY032-II I-shape straw packing machine..This equipment can box the U-shape straws,I-shape straws automaticly, it replace manual packaging greatly improving work efficiency.Replacement will reduce the amount of performance malfunctions created by manual labour.The entire of machinery is controlled through PLC.which has a stable performance and is easily operable.

Specifications

|

Driving motor |

Up-down |

0.75kw control by PLC |

|

|

Straws traction |

60w control by PLC |

|

|

Straws Swing |

60w control by PLC |

|

|

Box moving |

0.37kw control PLC |

|

Capacity |

600~700 pcs/min |

|

|

Operating method |

Automatic |

|

|

Machine size |

1600×1200×2000mm |

|

|

Machine weight |

800kg |

|

Configuration table of GD-059 U-shape straw boxing machine

|

|

Name |

Type |

Quantity |

Remark |

|

1 |

小马达Motor |

0.75KW |

1 |

西门子 Siemens |

|

2 |

减速机Reducer

|

WPO-50-10-B |

1set |

杭州誉球Hangzhou yuqiu |

|

4 |

变频器frequency converter |

0.4KW |

2sets |

台达Delta |

|

|

|

0.75KW |

1set |

|

|

5 |

PLC |

DVP40ES200T |

1set |

|

|

6 |

显示屏display |

TP04G-BL-C |

1台 |

|

|

7 |

接近开关proximity switch |

E2B-M12KS04-WP-C1 |

7pcs |

欧姆龙OMRON |

GD-W01

Automatic vision inspection machine for belted straws:

The system uses visual inspection technology for on-line quality inspection in the production process of belted famat paper straws; Including lack straw, flattening straw, abnormal length

system parameter:

System structure:Frame (stainless steel)

Electric control box (including circuit breaker, switching power supply, PLC etc).

3. Microcomputer: i5,32g solid state disk, double gigabit network port

4. Screens

5. working voltage:220VAC

6.Rated power:1250W

7.Industrial camera: global shutter, Gigabit Ethernet.

computar:16mm

Industrial visual light source:2

8. Light source controller:2

machine size:1500*900*1700mm

|

|