Features

GD-700D

Product Description

Feature

GD-Slitting machine can be used for straw paper, copper /aluminum foil, reflector film, plastic film, conductive fabric slitting work, and also suit for other materials.

1. Two winding shafts, more efficency;

2. Air expanding shaft, clamp more tighten, no slippage;

3. Tension controllable and output torque balancing by magnetic powder brake actuator;

4. High speed waste material blowing fan;

5. Fast closing to knife device, locking upper knife shaft

|

|

Introduction

Paper Slitting and Rewinding Machine is the equipment that cuts a large roll of paper, film, non-woven fabric, aluminum foil, mica tape and other thin materials into different width of small volumes before and after printing, which is commonly used in paper manufacturing machinery, printing and packaging machinery.

Specification & Parameter

|

GD-700 Slitting Machine |

|||

|

Max Unwinding Width |

700mm |

Max Rewinding Width |

600mm |

|

Max Unwinding Diameter |

1000mm |

Max Rewinding Diameter |

600mm (420mm) |

|

Slitting Thickness |

20-120g/ m2 |

Slitting Speed |

10-150m/min |

|

Unwinding roller shaft |

76mm Diameter |

Rewinding roller shaft |

76mm Diameter |

|

Motor Power |

7.5 Kw |

Converter |

11 Kw |

|

Main Part Dimension |

2100*1300*1000mm |

Unwinding Part Dimension |

1600*1650*1000mm |

|

Weight |

2100 Kg |

|

|

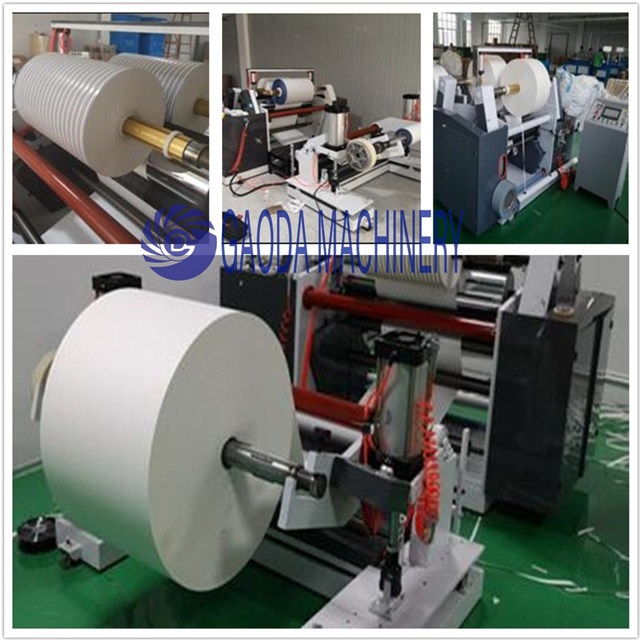

Detailed Images

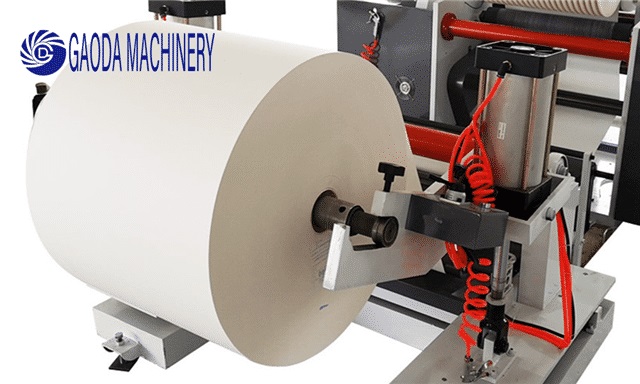

Unwinding Mechanism

Unwinding materials into the slitting mechanism. Adopt magnetic brake unit, the unwinding mechanism could be tension controllable and speed balancing. Paper roller pneumatic/air shaft can be adjusted vertically and horizontally by hand to wipe off the tension difference caused by different thickness at two ends of the shaft.

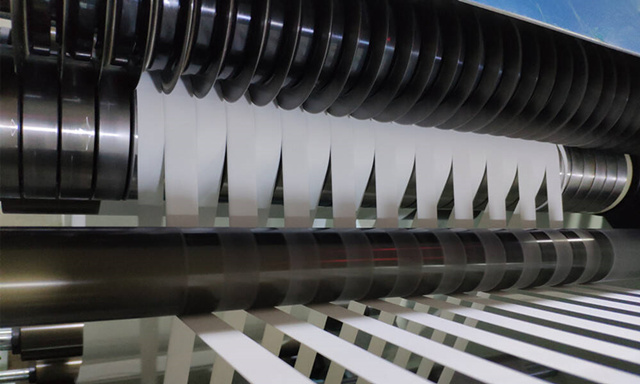

Slitting Mechanism

Adopt carbide precision disc knife or straight knife, neat incision, long life, up and down cutting knife shaft width controllable. The speed of upper and lower knife shaft are controlled and distributed by gears. Turn the handwheel to drop down the knife, and it will close to materials automatically

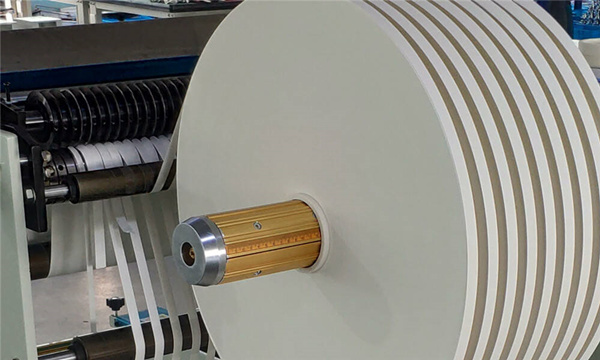

Rewinding Mechanism

Adopt left-right axis biaxial winding with pressure arm balance internal and external pressure. The transmission uses two independent magnetic particle motor drive uniaxial tensions adjustable.

Transmission Mechanism