Whole Line 9knives 100m High Speed Paper Straw Making Packing Machine

Features

Technical Parameter

Working Principle and short instruction:

Winding/spiraling different layers paper strip into paper tube with glue.

Multi-cutting knife system, by servo tracking, cut paper tube into small piece of paper drinking straws.

Material: food grade white craft paper and food grade glue.

Sub-raw material: may need oil for lubrication and cooling. White mineral oil.

Standard electric power: 380V/ 3phase/ 50Hz, could change by special requirement, like 60Hz or 220V/ 3 phase.

Electric consumption: Rated power, 6.15KW/h

FLA( Full load amp): 13.5A

Capacity:

How many pieces straw per minute. For example: 80m/min, making 6*197mm straws. Consider some waste, we use 200mm for calculating.

80*1000/200=400 pcs/minute.

Need to move the mandrel to left a bit ,the belt can not exceed the mandrel right end

100M high speed paper straw machine(5 servo motors)

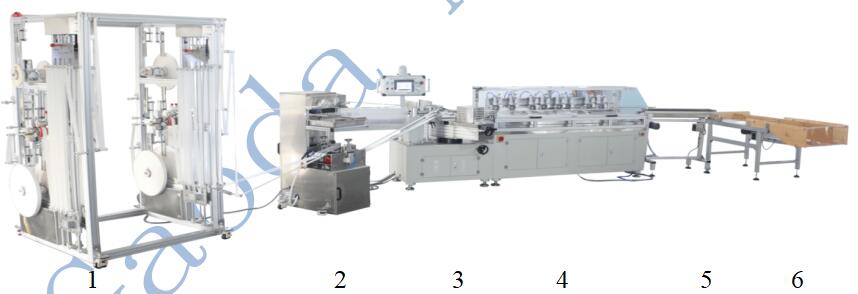

Total machine includes 6 parts: from left to right side

- Paper roll hanging bracket, 4 layers, auto connecting/splicing;

- Glue station, stainless steel, glue auto feeding;

- Winding and control mechanism;

- Muti-cutting system, 9 cutting knives with dust & protecting cover;

- Conveyor;

- Collector.

Advantage of GDM-30

- Higher Speed,max 120m/min input, 95m/min out put.

- 9 cutting-knife system, new structure of cutting cylinder. Easier to adjust air cylinder up and down when making different diameter paper straws.

- 5 sets servo motor for spiraling roller, cutting system moving left & right, supporting roller and cutting knifes.

- Auto paper roll connecting function hanging bracket, auto splicer, 4 layers. Other brand paper straw making machine paper roll hanging bracket is only 3 layers.

- Auto feeding function glue station.

- Auto lubrication grease feeding system for cutting system.

- Main electric parts choose famous brand, Schneider. Like main servo motor, servo motor driver, frequency converter, touch screen .

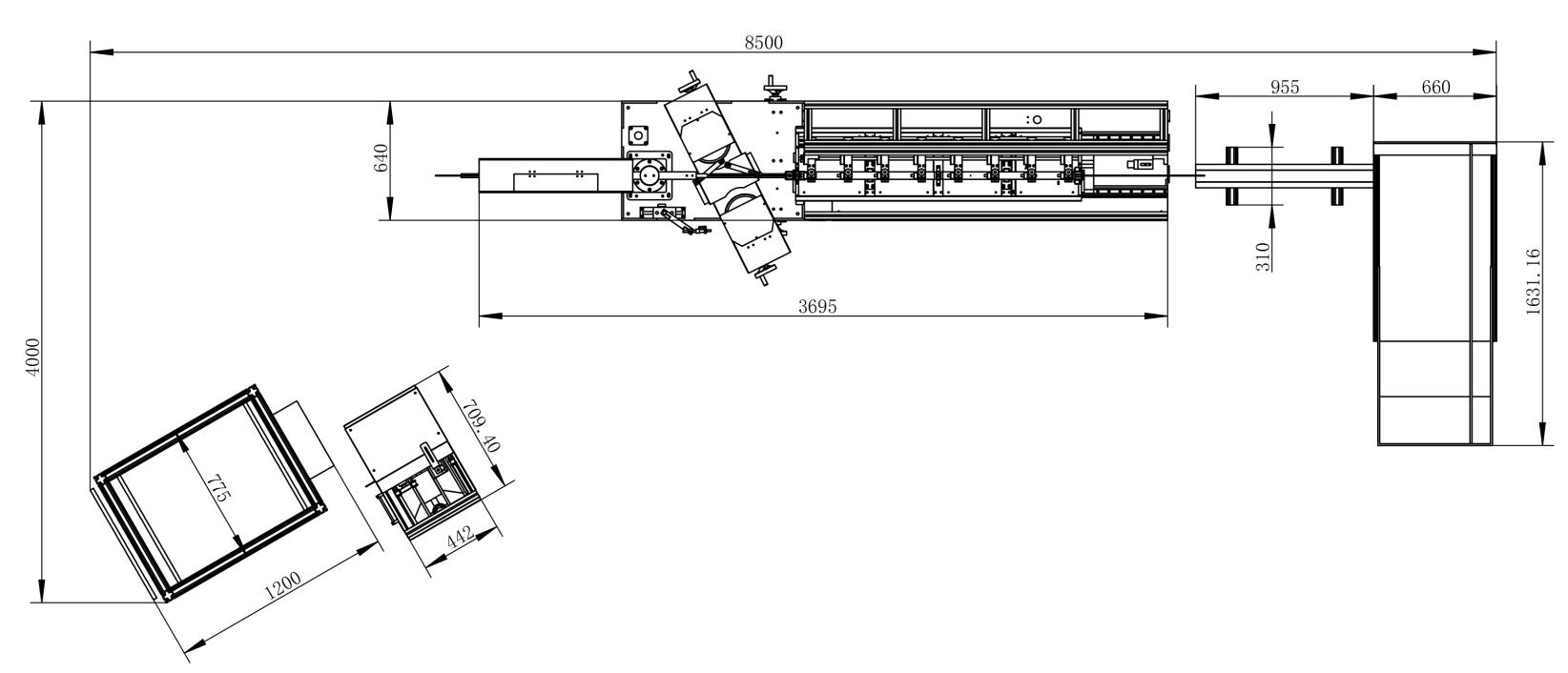

Overall size

Different unit dimension

|

Unit Name |

Dimension (mm) |

Unit Name |

Dimension (mm) |

|

Winding & control unit |

1720*1050*1680 |

glue station |

670*720*1430 |

|

Multi-cutting system |

1950*650*1450 |

Conveyor |

1200*400*1050 |

|

Paper roller bracket |

1120*1300*2050 |

Straw Collector |

1650*520*1080 |

Specification and Parameter

|

Model number |

100M high speed paper straw making machine (GDM-30) |

||

|

Technical parameter |

Control system |

||

|

Layer of paper |

3-4 layers |

PLC controller |

Schneider |

|

Max. diameter |

12mm |

Human machine interface |

Schneider |

|

Min. inner diameter |

3.5mm |

Program version |

GD-XJ3.0 |

|

Max. thickness |

1mm |

Servo system |

Schneider |

|

Min. thickness |

0.2mm |

Performer |

Schneider |

|

Min. length |

90mm |

Max.length(between 2 blades) |

1580mm |

|

Output speed |

3-110m/min |

Signal component |

Omron |

|

Winding system |

2 servo/1 pc belt |

Pneumatic component |

Airtac |

|

Cutting way |

9 knives pneumatic/1 servo |

synchronous control |

Synchronous belt |

|

Glue method |

Double side/single side |

Sync tracking cutting system |

Servo sync tracking system |

|

Lenght control |

encoder |

assemble |

|

|

Operator |

1 person |

Tube rack |

Have |

|

Mandrel fixing |

Screw clamp |

Belt angle adjustment |

Wheel adjustment |

|

Speed control |

servo |

Belt tension adjustment |

Wheel adjustment |

|

Power input |

3P/380V/50HZ |

Paper-break stop function |

have |

|

Dimension |

Glue method |

Schutze glue spray system |

|

|

Machine dimension |

4250×640×1600mm |

Lubrication |

Electric roller |

|

Floor area |

9500×3500×1900mm |

Paper tension control |

Continuous tension control |

|

Wheel diameter |

195mm |

Paper holder |

Automatic paper connecting holder |

|

Wheel height |

100mm |

Belt |

Piece baseband |

|

Max. spin speed |

200r/min |

Totalweight |

1350KGS |

Paper straw making mechanism

|

Cutting blade |

Mould Anti-vibration roller |

Pull rod force sensor |

electric socket and cooling fan |

Cutting blade material: W6Mo5Cr4V2

|

Unit Name |

Description and advantages |

|

Winding&control mechanism Multi-knife cutting system

|

Carbon steel; 5 sets servo motor; Dust & protect cover; Language: Chinese, English, Spanish, Polish, Vietnamese, Portuguese and so on; High and low voltage electric equipment separated isolation; Laser cutting and heat treatment to avoid micro shaking; Longer service life; Famous brand electric equipment: Schneider High speed and stable working; Safety labels for protecting method; |

|

2 auxiliary servo motor |

Main servo motor |

2 winding roller servo motors |

GD-XJ3.0

|

Automatic refueling device |

Stainless steel protective cover |

Glue Station

|

Unit Name |

Description and advantages |

|

|

Glue station |

Aluminum and stainless steel frame; Stainless steel glue pot; Glue recycle system Lubrication oil roller for inner paper strip; One pair roller ( rubber roller and steel roller) for filming glue on paper. 1 motor to drive glue roller; Easy to adjust glue quantity by adjust the distance of two roller. |

Paper roll hanging bracket with connecting function

|

Description and advantages |

|

1. Help paper straw making machine no stop working. 2. Use auto detection: When the paper roll is going to use out, the mechanism will cut the tail ends of old paper roll and connect new paper roll automatically. 3. Smaller dimension, easy delivery and moving to adjust paper feeding angle. 4. Construction simpleness. If paper break, no need to stop to route the paper up and down complicated. 5. Constant unwinding force for the paper rolls, to let paper feeding more smoothly. 6. Our own patent for this connecting mechanism, not copy from others, especially European brands, so no patent problem. 7. Optional choose: 4 layers connecting mechanism. |

Dryer for paper straw GD-Dryer

|

380V/3 phase/ 50Hz 9.6KW/h Dimension: 2.3*0.7*1.02m 0-10m/min; 120kg Could exchange with collector |

Lifter conveyor

|

Cooperate with other machines, like packing machine, counting machine. 6/8/10mm diameter Let working easier. |

Single Packing&mutlti packing

|

|