Features

GD-PRINT650 FLEXO PAPER PRINTING MACHINE

PRINTING MACHINC

1. Feature

1. Adopts ceramic mesh roller to convey ink.

2. Magnetic powder brake and clutch control the feeding and rolling or discharging.

3. Each printing unit adopts 360-degree registering adjuster.

4. Drying group with infrared drying device.

5. The inking roller can depart from the machine and rotate at low speed in order to keep the ink from drying when its stops.

6. The main motor adopts stepless governor converter.

Specifiation Parameter

|

S.N |

Main Technical Parameter |

Data |

|

1 |

Max Feeding Width |

1000mm |

|

2 |

Printing Speed |

80m/Min |

|

3 |

Printable Color |

4 Colors |

|

4 |

Max Web Width |

630mm |

|

5 |

Max printing Width |

620mm |

|

6 |

Printing girth |

180mm—720mm |

|

7 |

Main Motor Power |

5.5KW |

|

8 |

Power Supply |

380V 3PH 50Hz |

|

9 |

Plate Thickness |

1.7mm |

|

10 |

Paste version tape thickness |

0.38mm |

|

11 |

The thickness of the substrate |

180g-420g |

|

12 |

Overprint precision |

±0.12mm |

|

13 |

Total Power |

18KW |

|

14 |

Machine dimension |

2.8*1.6*2.4m |

|

15 |

Machine weight |

About 2900KGS |

Machine Construction

1)Unwinder unit: one set

Max Paper roller diameter 1000mm

One 3inch air swelling shaft (can change to 6 inch air swelling shaft)

Auto tension control system of unwinding and rewinding

One Magnetic powder brake.

With Fast inflating gun.

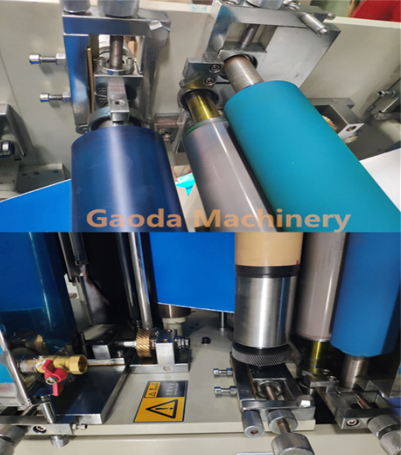

2)Printing unit:4 sets, 4 colors

The printing unit adopt 45 degrees of DP13 helical gear structure

Reserved image detection station

Anilox rolle, printing roller pressure pneumatic clutch

Ceramic Anilox roller 4pcs (as require)

Priting roller 8pcs (as require)

Manual transverse focusing alignment 4 set

Manual vertical focusing alignment 4 set

Single pole reverse scraping system 4set

Stainless steel cartridge 4set

Fast changing plate cylinder without any tools

Anilox roller rotation function: when machine stoped the anilox roller still running automatically, to prevent ink dry on anilox roller, avoid the anilox roller plug.

4 The printing gear:cp1/8

3)Heating and drying unit

Heating power :20KW

Fans:2.2KW*2PCS 1.5KW*2PCS

IR Dryer (one set)

Infrared heating drying printing unit,IR 4set

4)Rewinder unit

A set of winding for rewinding after printing, with one 3inch air swelling shaft can change 6inch air swelling shaft

Max rewinding diameter 1000mm

5)Web guiding unit

One set of Paper binding table

The paper guide roller adopts high hardness anodized

Adopt the ball screw electric actuators

Adopt rectifying photoelectric head to rectify induction

Electronic paper web guide traction device, there was a small offset paper web movement, the system can accurately continuously revised

Guiding precision:±0.12mm