Features

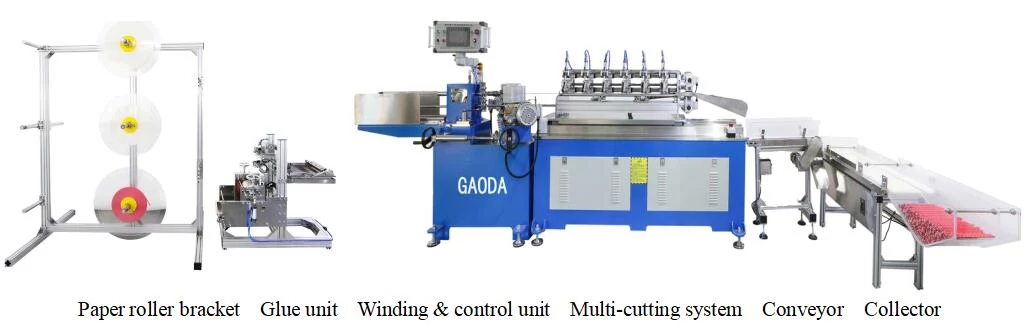

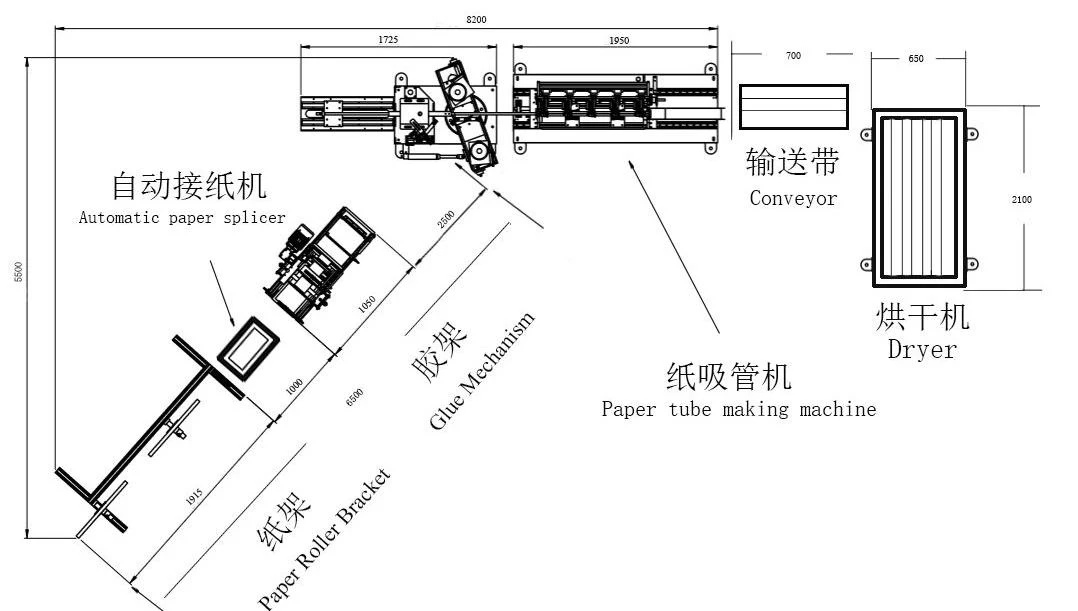

Layout Drawing: 8.2*5.5 meter. (26.9*18 foot). More set, land area will decrease.

The dryer and collector can exchange.

Difference between normal with faster model

|

S.N |

Normal model |

Faster model |

|

5 pcs straws per cutting |

||

|

Cutting blade |

6 |

6 |

|

Max paper tube length |

1100mm |

1100mm |

|

Max speed |

50m/min |

60m/min |

|

Stable speed |

30-45m/min |

35-52m/min |

|

Price |

15000USD |

16300USD |

|

Automatic paper strip splicer |

||

|

Capacity: How many pieces straw per minute. For example: 40m/min, making 6*197mm straws. Consider some waste, we use 200mm for calculating. 40*1000/200=200 pcs/minute. How to judge the output speed: For 6 cutting blade model, 40m/min output speed, 5*197=985mm, nearly 1 meter. The cutting system need drop off nearly 40 times per minute in videos. U could set total paper tube length in panel. 5*197=985mm. When paper tube arrives 985mm, the cutting blade drop down and cut into straws.It’s better to set 1000mm for paper tube length, waste a little at end to make last straw the same length with other straws. |

||

Remark

The speed above is paper tube output speed, not paper feeding speed. Some company use paper feeding speed to attract customer on YouTube.

To get a good quality and stable & no stop working, we suggest use a slower speed.

Different unit dimension

|

Unit Name |

Dimension (mm) |

Unit Name |

Dimension (mm) |

|

Winding & control unit |

900*770*1700 |

Glue unit |

1000*680*1005 |

|

Multi-cutting system |

1950*800*1500 |

Conveyor |

710*310*890 |

|

Paper roller bracket |

1620*810*1920 |

Straw Collector |

1680*350*890 |

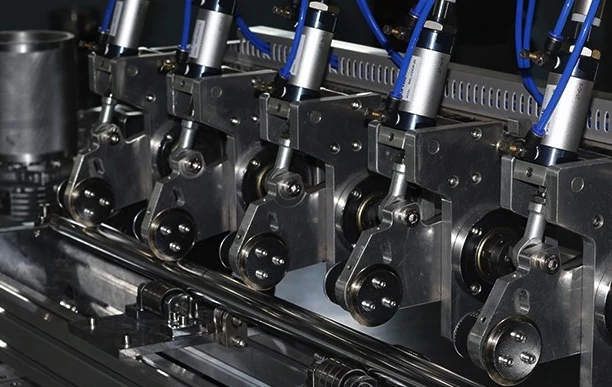

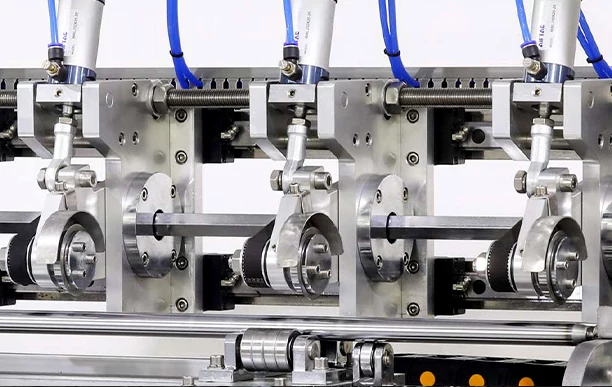

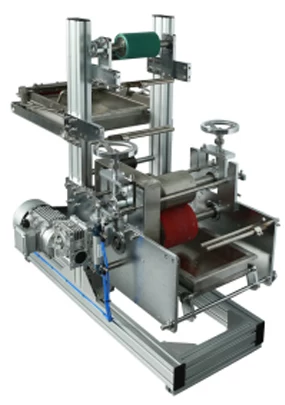

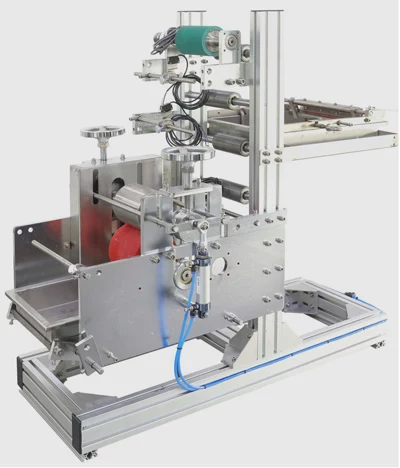

Paper straw making mechanism

The working table is covered by stainless steel, enough for putting tools, like spanner, screwdriver, to forbid scratch on color painting.

|

|

|

|

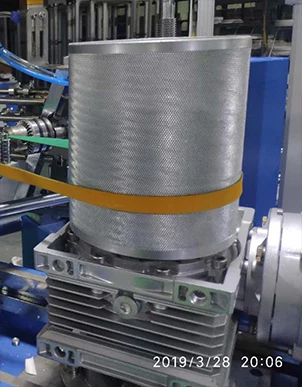

New winding roller |

Old winding roller |

|

|

W6Mo5Cr4V2 Cutting blade |

|

|

Gaoda frame body |

other brand frame body |

|

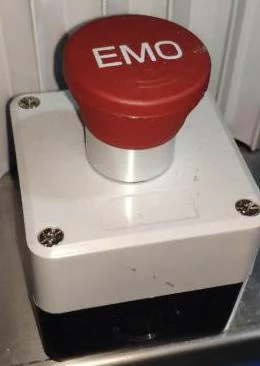

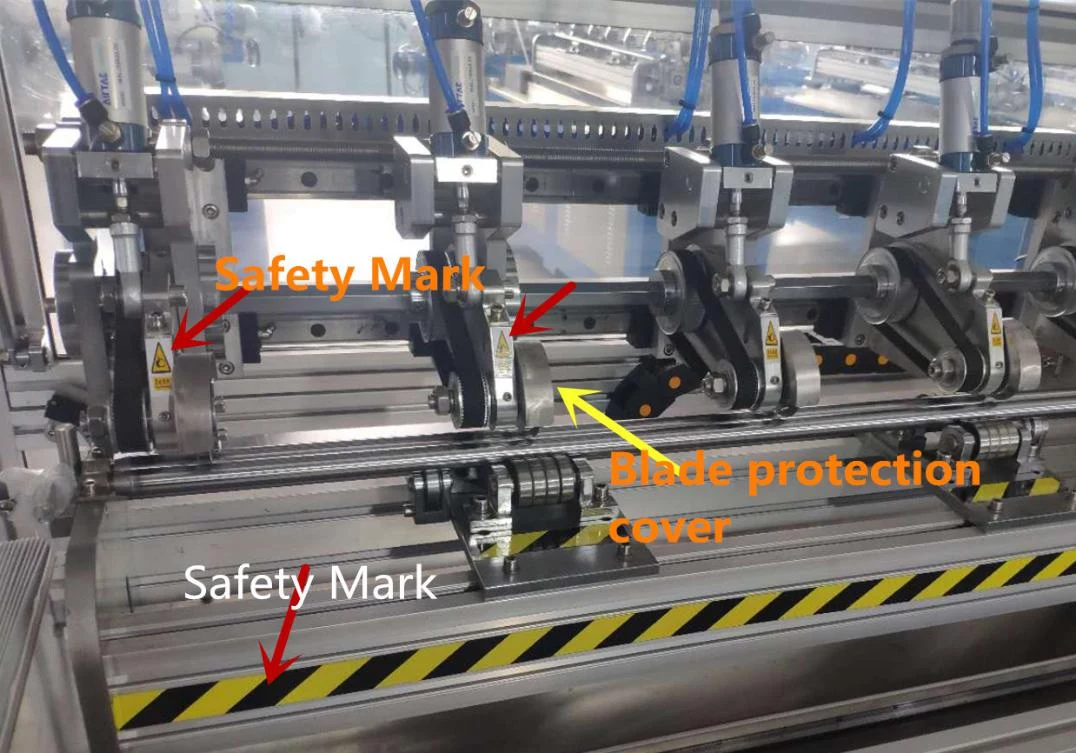

For protecting the operator: 1.Safety mark at different danger position; 2.Cutting blade protection cover; 3.Emergency stop button at both side of the machine.

|

|

Unit Name |

Description and advantages |

Remark |

|

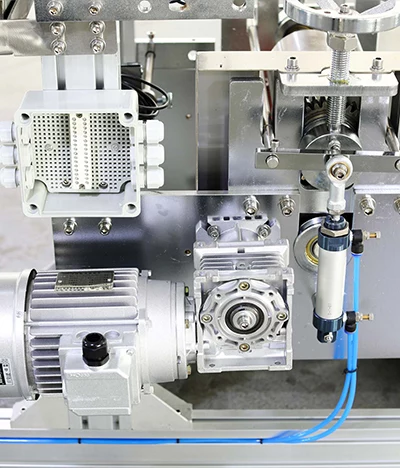

Winding & control unit Multi-cutting system |

Carbon steel; Laser cutting and heat treatment to avoid micro-shaking; Longer service life. Famous brand electric equipment |

Optional choice:

|

|

Technical Parameter |

|||

|

Paper layer |

2~5 layers |

Fixed length |

Enbcoder |

|

Inner diameter |

6~12mm |

Operator |

1~2 staff |

|

Thickness |

0.3~1mm |

Speed control |

Servo motor |

|

Speed |

0~60m/min |

Power supply |

380V/ 3 phase/ 50Hz |

|

Cutting length |

120~1050mm |

Glue method |

Three layer spray type |

|

Way of Gluing |

Single/double side |

Weight |

1350kg |

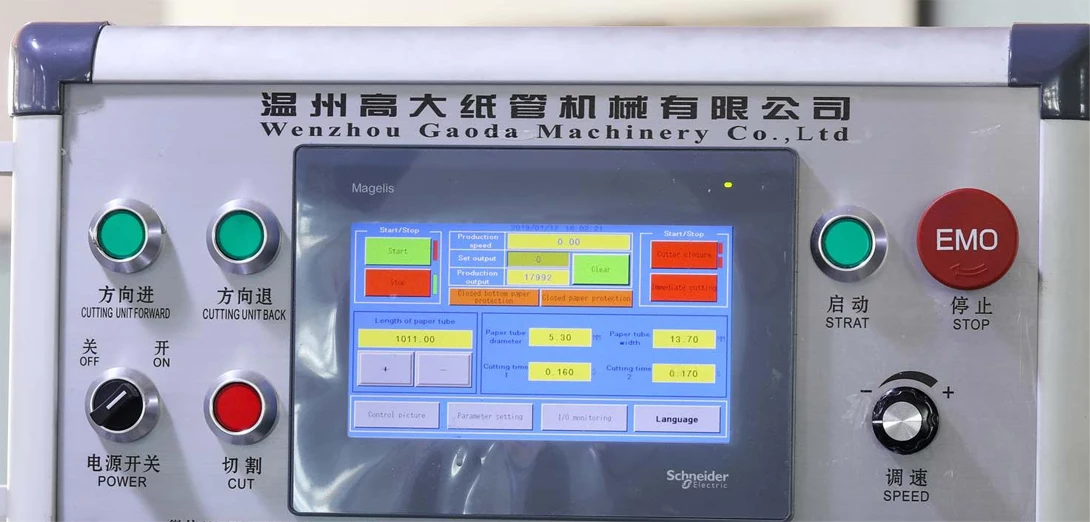

Adopted man-machine control interface, touch screen parameters setting, easy for operating. Controlled by encoder, driven by servomotor. Automatic and high efficiency.

Select and use famous brand suppliers for motor and electrical equipment. Thermal/heat treatment frame to remove internal stress to keep longer service life.

Main equipment supplier

|

Parts Name |

Picture |

Brand |

|

PLC & Interface |

|

Schneider: (France brand) Schneider Electric is leading the Digital Transformation of Energy Management and Automation. With CE and UL certification Language: Chinese, English Spanish, Vietnamese |

|

Servo motor |

|

Schneider: With CE and UL certification |

|

Servo motor driver |

|

Schneider: With CE and UL certification |

|

Frequency charger (Frequency converter) |

|

Schneider: With CE and UL certification |

|

Switch Intermediate relays Circuit breaker |

|

Schneider: With CE and UL certification |

|

Air filter Air cylinder |

|

|

|

Winding motor*2 Cutting blade motor*1 Supporting roller motor*1 |

|

Cooperate with Germany Has special 60Hz motor

|

|

Unit Name 单位名称 |

Description and advantages 产品描述 |

|

Paper roller bracket 纸架 |

1620*810*1920mm; 铝框 Aluminum frame; 6支托辊杆 6 supporting rods for paper rollers; (如果装运时没有足够的空间,可以拆卸支架) (If not enough space when shipping, the bracket could be disassemble) |

|

|

纸辊安装在T型钢上,转动灵活。根据纸层的要求,可放置2~6个纸辊 The paper roller can be easily installed on the T-bar and rotate flexibly. According to the requirement of paper layers, you can put 2~6 paper rollers. |

||

|

Unit Name |

Description and advantages |

Remark |

|

Glue unit |

1000*680*1005mm Interruption sensor of paper *2; Aluminum frame; Stainless steel glue pot; Air cylinder, 2 pcs; More rollers to keep constant tension of paper strip; 1 motor to drive glue roller; Encoder |

Standard: 3 layers Optional choice: 4 layers 5 layers |

|

|

Choose gluing single side or double sides. Automatically lift up and drop off. The drinking straws are glued evenly and sticked firmly. |

|||

|

|

|

|

Unit Name |

Dimension (mm) |

Description and advantages |

Remark |

|

Conveyor |

710*310*890 |

Aluminum frame; Speed controllable 220V, 1 phase, 50Hz |

|

|

Straw Collector |

1680*350*890 |

Aluminum frame; Speed controllable 220V, 1 phase, 50Hz |

If don’t want collector, you can choose dryer for exchange |

|

|

1.6 blades model, standard specification is 380V, 3 phase, 50Hz. If you need other voltage or 60Hz motor, tell us advance.

2.Standard is for making 3 layers, which could make 2 or 3 layers straws.

Up to now, the paper straw is 3 layers. If you want make more layers, 4 or 5, the glue unit and paper reel bracket need change, also the material cost increase.

4 layer straw is harder than 3 layers. I think, for 10-12mm paper straws, it’s better use 4 layers.

3.6 blade model is for making 6-12mm straws. Different diameter need different molds. The mold includes 3 parts: thinner pull rod, mandrel and cutting mat.

If you want to make 4 and 5mm straws, need special model..

Payment term and after-sale service

Term |

|

Packing: Plastic film package or Wooden box(Optional, need pay) |

|

FOB Price: Sea Freight cost & Insurance are paid by the buyer. |

|

Payment: T/T; 30% down payment, the balance 70% to be paid before shipment. |

|

Lead time: Ordinary model, 7-15 days after receiving the down payment.(to be postponed if meet legal holidays and special design, customize requirements like dust cover...... ). Stainless steel body model is 25-30days. |

|

Training & Service: We suggest that customers take a training for 3-5 days at our factory for installation and operation. How to change paper straw length and diameter, how to judge glue quantity and viscosity. Training at our factory is free. If on-site installation and training, the buyer need pay round tickets cost(from Wenzhou to your factory and return Wenzhou from your factory),food and hotel. What’s more, salary for engineer USD100 per day. |

|

2*Interuption sensors |

Blocking sensor |

Glue heating unit |

For glue heating unit: If your workshop temperature is suitable, don’t need to use or open the glue heating function. Because the temperature will influence the glue viscosity, that’s very important for glue performance. Too thickness or too thinning are both bad for making paper straws.

What’s more, the glue hearing unit will dry the glue easily to stick on the glue pot, make cleaning work more difficult. The glue unit pot need clean everyday after working.

Interuption sensors:When the paper break,and no paper strip go through the glue unit, the paper straw making machine will stop by itself.

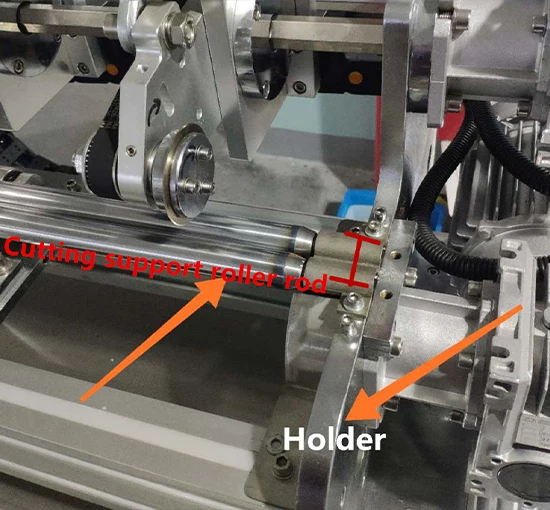

Note: But if you want make 5mm (mandrel is 4.3mm), the only choose is shorter frame body model. Because the mandrel and cutting mat are thinner, if cutting mat too long, it will easier shaking during working. What’s more, the cutting support roller rod should also be thinner, if not, the cutting blade could not touch paper tube on cutting mat.

|

|

|

The paper strip width and specification for different diameter straw:

Normally the paper drinking straws need 3 layers. Both paper and glue materials are food grade.

Here are the specifications for paper strip width:

|

S.N |

Straw Diameter |

Paper layer |

Width (mm) |

Remark for slitting knife |

Weight |

|

1 |

4-5 mm |

Inner |

10.5 |

1 set slitting knife |

120g/sq m |

|

|

|

Middle |

11 |

|

120g/sq m |

|

|

|

Outter |

12 |

1 set slitting knife |

60g/sq m |

|

2 |

6-10 mm |

Inner |

13.5 |

1 set slitting knife |

120g/sq m |

|

|

|

Middle |

14 |

|

120g/sq m |

|

|

|

Outter |

15 |

1 set slitting knife |

60g/sq m |

|

3 |

10-12mm |

Inner |

17.5 |

1 set slitting knife |

120g/sq m |

|

|

|

Middle |

18 |

|

120g/sq m |

|

|

|

Outter |

19 |

1 set slitting knife |

60g/sq m |

|

Dust & Protection Cover |

Stainless steel cover model |

Whole frame body stainless |

|

Other optional choice price |

|||||

|

Product Name |

Model |

Unit |

Unit Price (USD) |

Remark |

Code |

|

Multi-blade paper straw making machine for 4.2 and 5mm paper straws, 7+ cutting blades |

GDM5-1S |

Set |

16800 |

shorter body |

B1 |

|

Stainless steel cover (optional) |

|

Set |

+1000 |

optional |

O1 |

|

Whole frame body stainless steel (optional) |

|

Set |

+2250 |

optional |

O2 |

|

Dust & protection cover (Optional) |

|

Pcs |

+800 |

optional |

O3 |

|

Dryer (Optional) |

GD-Dyer |

Set |

+1100 |

optional |

O4 |

|

4 layers glue unit and paper reel bracket (Optional) |

|

Set |

+300 |

optional |

O4 |

The price of paper straw making machine includes winding & control unit, multi-blade cutting unit, glue unit, paper reel bracket, conveyor & collector. Not include dust cover and dryer. Not includes the optional choose.

Main free parts for paper straw making machine:

- 12 cutting blades;

- 3 sets paper straw mold;

- 1 air cylinder.

- 15 winding belts;

- 1 cutting blade belts

|

Parts Name |

Picture |

Quantity |

|

Cutting blade |

|

12 pcs/set |

|

Winding belt |

|

15 pcs/set |

|

Straw mold |

|

1 set of mold including: Thinner pull rod Mandrel Cutting mat 3 set mold for free |

|

Air cylinder |

|

1 |

|

Cutting blade belt |

|

1 |

Delivery list

|

S.N |

Product Name |

|

1 |

Name:Multi-blade paper straw making machine, 5 or 6 blades |

|

2 Deliver List |

1. Multi-blade cutting system, 1.5KW, 1 set. 2. Winding and control system, 1 set. 3. Two-line vertical paper reel bracket. 4. Glue unit. 5. Conveyor and collector. 5. Mold of paper straw, 3 kinds, choose by customer. Including cutting mat, thinner pull rod, mandrel 6. Cutting mat, 3 pcs with mold. 7. Pull rod 6 pcs: together with paper straw mold 8: Drill chuck: 1 set. 9. Blades: 10 pcs 10. Winding belt: 1700*15*1, 10 pcs. 11. Solenoid valve, 1 pcs, 24V. 12. Air cylinder: CDQ2A, 20*25-10, 1 pcs. 13. Air cylinder adjusting valve, 4 pcs. 14. Tools: 1 set. 15. Location limited switch: TL-Q5MC1-Z, 1 pcs. 16. 8mm, 3-way jointer, 3 pcs. 17. 8mm, 2-way jointer, 3 pcs. 18. 8-6mm, jointer, 2 pcs. 19. 8mm, air tube, 10m. 20. Plastic paper clamp plate, 12 pcs. 21. Paper reel fixing ring, 12 pcs. 22. Paper reel fixing plate, 12 pcs. 23. Belt, 426-3M-15, 5 Pcs 24. P204 bearing, 1 pcs. 25. Metal glue-502, 2 pcs. |

|

|

|