Features

Technical Parameter

Working Principle and short instruction:

- Winding/spiraling different layers paper strip into paper tube with glue.

- Multi-cutting knife system, by servo tracking, cut paper tube into small piece of paper drinking straws.

- Material: food grade white craft paper and food grade glue.

- Sub-raw material: may need oil for lubrication and cooling. White mineral oil.

- Standard electric power: 380V/ 3phase/ 50Hz, could change by special requirement, like 60Hz or 220V/ 3 phase.

- Electric consumption: Rated power, 6.15KW/h

- FLA( Full load amp): 13.5A

Capacity:

- How many pieces straw per minute. For example: 80m/min, making 6*197mm straws. Consider some waste, we use 200mm for calculating.

- 80*1000/200=400 pcs/minute.

100M high speed paper straw machine(5 servo motors)

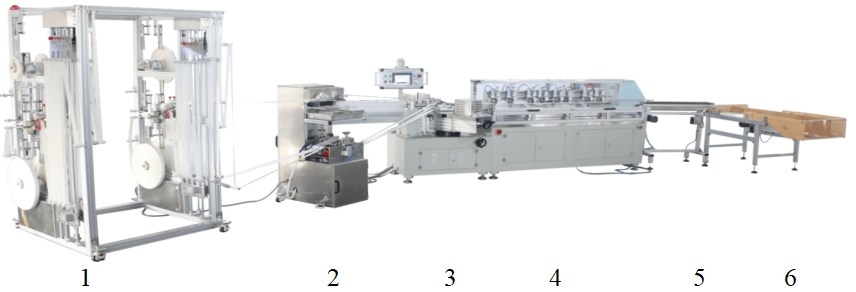

Total machine includes 6 parts: from left to right side

- Paper roll hanging bracket, 4 layers, auto connecting/splicing;

- Glue station, stainless steel, glue auto feeding;

- Winding and control mechanism;

- Muti-cutting system, 9 cutting knives with dust & protecting cover;

- Conveyor;

- Collector.

Advantage of GDM-30

- Higher Speed,max 120m/min input, 95m/min out put.

- 9 cutting-knife system, new structure of cutting cylinder. Easier to adjust air cylinder up and down when making different diameter paper straws.

- 5 sets servo motor for spiraling roller, cutting system moving left & right, supporting roller and cutting knifes.

- Auto paper roll connecting function hanging bracket, auto splicer, 4 layers. Other brand paper straw making machine paper roll hanging bracket is only 3 layers.

- Auto feeding function glue station.

- Auto lubrication grease feeding system for cutting system.

- Main electric parts choose famous brand, Schneider. Like main servo motor, servo motor driver, frequency converter, touch screen .

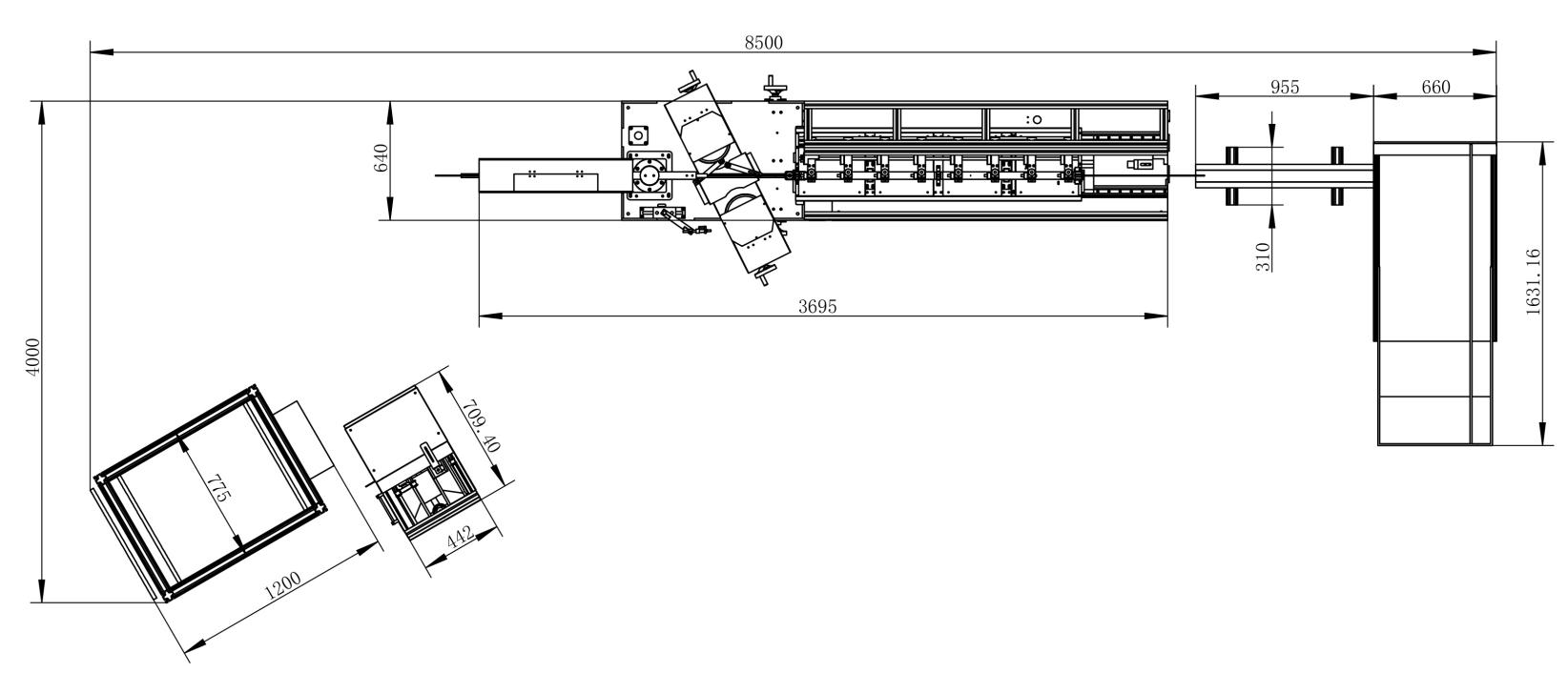

Overall size

Different unit dimension

|

Unit Name |

Dimension (mm) |

Unit Name |

Dimension (mm) |

|

Winding & control unit |

1720*1050*1680 |

glue station |

670*720*1430 |

|

Multi-cutting system |

1950*650*1450 |

Conveyor |

1200*400*1050 |

|

Paper roller bracket |

1120*1300*2050 |

Straw Collector |

1650*520*1080 |

Specification and Parameter

|

Model number |

100M high speed paper straw making machine (GDM-30) |

||

|

Technical parameter |

Control system |

||

|

Layer of paper |

3-4 layers |

PLC controller |

Schneider |

|

Max. diameter |

12mm |

Human machine interface |

Schneider |

|

Min. inner diameter |

3.5mm |

Program version |

GD-XJ3.0 |

|

Max. thickness |

1mm |

Servo system |

Schneider |

|

Min. thickness |

0.2mm |

Performer |

Schneider |

|

Min. length |

90mm |

Max.length(between 2 blades) |

1580mm |

|

Output speed |

3-110m/min |

Signal component |

Omron |

|

Winding system |

2 servo/1 pc belt |

Pneumatic component |

Airtac |

|

Cutting way |

9 knives pneumatic/1 servo |

synchronous control |

Synchronous belt |

|

Glue method |

Double side/single side |

Sync tracking cutting system |

Servo sync tracking system |

|

Lenght control |

encoder |

assemble |

|

|

Operator |

1 person |

Tube rack |

Have |

|

Mandrel fixing |

Screw clamp |

Belt angle adjustment |

Wheel adjustment |

|

Speed control |

servo |

Belt tension adjustment |

Wheel adjustment |

|

Power input |

3P/380V/50HZ |

Paper-break stop function |

have |

|

Dimension |

Glue method |

Schutze glue spray system |

|

|

Machine dimension |

4250×640×1600mm |

Lubrication |

Electric roller |

|

Floor area |

9500×3500×1900mm |

Paper tension control |

Continuous tension control |

|

Wheel diameter |

195mm |

Paper holder |

Automatic paper connecting holder |

|

Wheel height |

100mm |

Belt |

Piece baseband |

|

Max. spin speed |

200r/min |

Totalweight |

1350KGS |

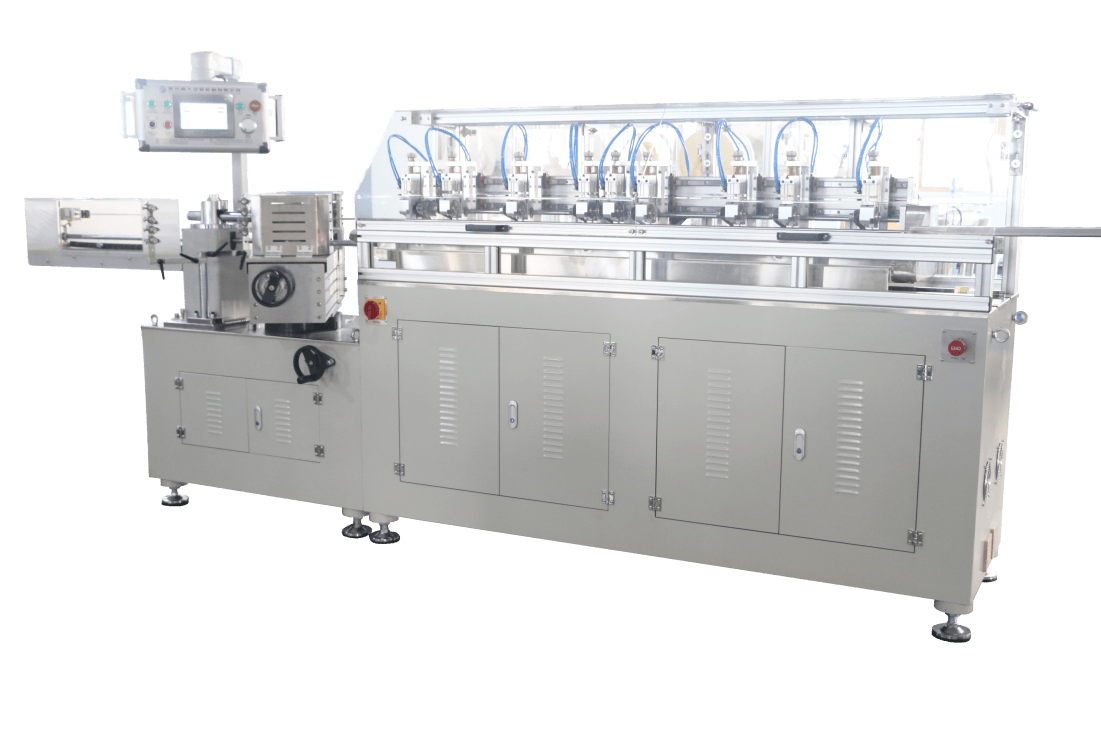

Paper straw making machine

|

Cutting blade |

Mould Anti-vibration roller |

Pull rod force sensor |

electric socket and cooling fan |

Cutting blade material: W6Mo5Cr4V2

|

Unit Name |

Description and advantages |

|

Winding&control mechanism Multi-knife cutting system

|

|

|

2 auxiliary servo motor |

Main servo motor |

2 winding roller servo motors |

|

GD-XJ3.0 |

Automatic refueling device |

Stainless steel protective cover |

Glue Station

|

Unit Name | Description and advantages |

| Glue station |

|

Paper roll hanging bracket with connecting function

|

Description and advantages |

|