Whole Line Of Gaoda 8 Cutting Knives Paper Straw Making Machine

Features

Wenzhou Gaoda Paper Tube Machinery Co.,Ltd is a leading supplier of paper straw machinery and equipment in China. Gaoda established at 2015, have engineers which experienced more than 10 years at paper tube/pipe machines. We design paper straw making machine from 5cutting knives to 6,7 and 8 pcs cutting knives. Improve machine stable working and working speed. Gaoda machines could make products from straight paper straws to sharp end paper straws, bend (flexible) paper straws. We have solution for individual/single packing, bulk/group packing, paper carton/box packing and tetra packing for soft drinks.

Catalogue

- Working Principle and Short Instruction

- New 8 Cutting Knife Paper Straw Making Machine

- Payment Term and After-sale Service

- Other Things for Consideration

- Main Free Parts with Machine

- Gaoda Factory

Working Principle and short instruction

Winding/spiraling different layers paper strip into paper tube with glue.

Multi-cutting knife system, by servo tracking, cut paper tube into small piece of paper drinking straws.

Material: food grade white craft paper and food grade glue.

Sub-raw material: may need oil for lubrication and cooling. White mineral oil.

Standard electric power: 380V/ 3phase/ 50Hz, could change by special requirement, like 60Hz or 220V/ 3 phase.

Electric consumption: Rated power, 6.15KW/h

FLA( Full load amp): 13.5A

Capacity

How many pieces straw per minute. For example: 70m/min, making 6*197mm straws. Consider some waste, we use 200mm for calculating.

70*1000/200=350 pcs/minute.

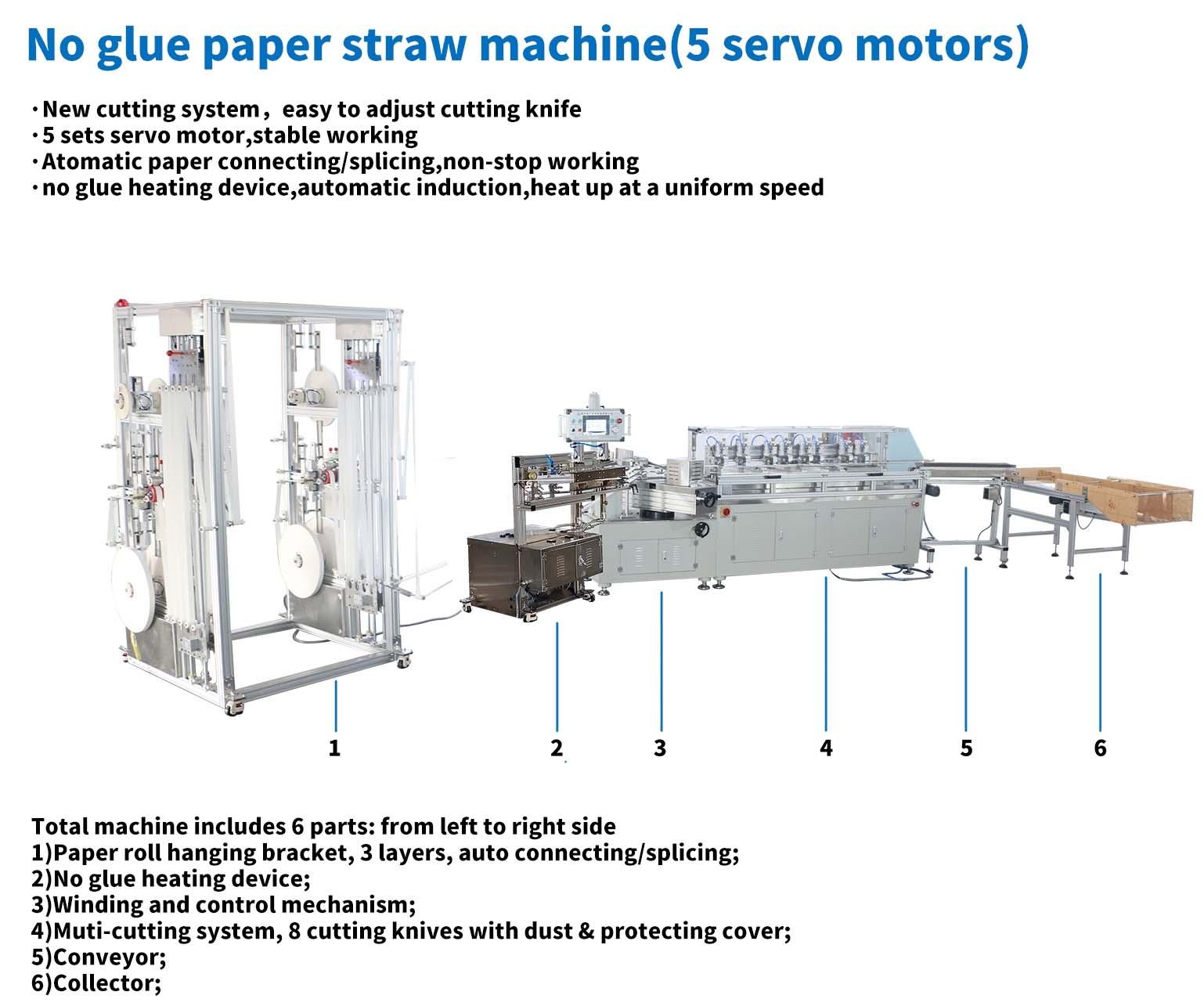

New 8 Cutting Knife Paper Straw Making Machine

Advantage of GDM-20

- Higher Speed,max 105m/min input, 80m/min out put.

- 8 cutting-knife system, new structure of cutting cylinder. Easier to adjust air cylinder up and down when making different diameter paper straws.

- 5 sets servo motor for spiraling roller, cutting system moving left & right, supporting roller and cutting knifes.

- Auto paper roll connecting function hanging bracket, auto splicer, 4 layers. Other brand paper straw making machine paper roll hanging bracket is only 3 layers.

- Auto feeding function glue station.

- Auto lubrication grease feeding system for cutting system.

- Main electric parts choose famous brand, Schneider. Like main servo motor, servo motor driver, frequency converter, touch screen .

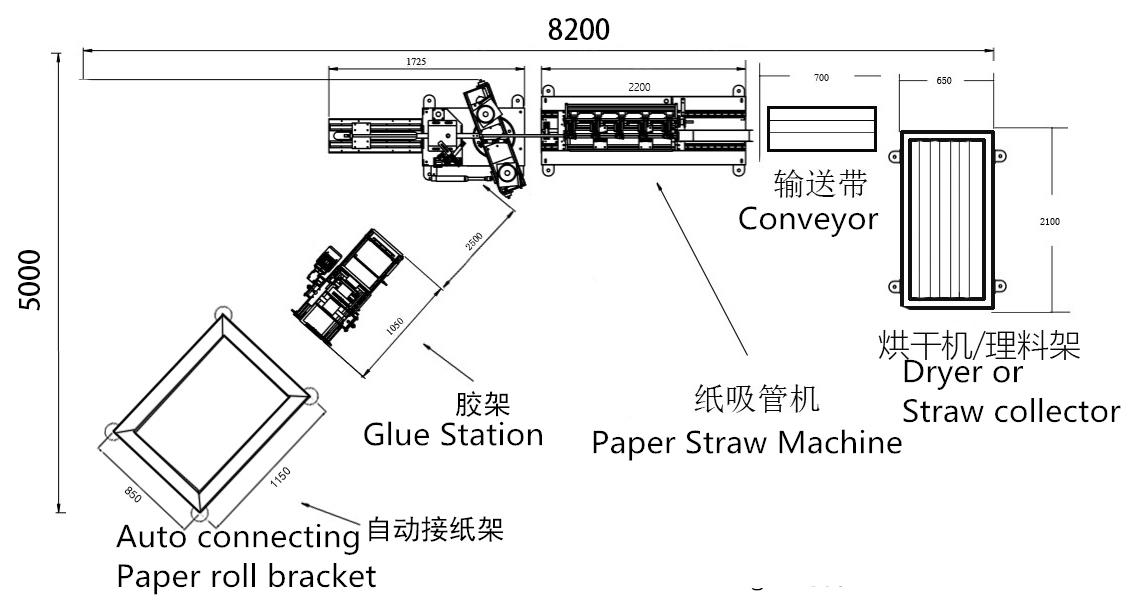

Different unit dimension

|

Unit Name |

Dimension (mm) |

Unit Name |

Dimension (mm) |

|

Winding & control unit |

900*770*1700 |

glue station |

720*630*1360 |

|

Multi-cutting system |

1950*850*1370 |

Conveyor |

710*310*890 |

|

Paper roller bracket |

1030*1030*2200 |

Straw Collector |

1680*350*890 |

Specification and Parameter

|

Model |

GDM-20 |

||

|

Technical Parameter |

Main Parts |

||

|

Electric power |

380V/ 3phase/ 50Hz |

PLC |

PanKong |

|

Electric consumption |

4.5-6.5Kw/h |

Control screen |

Schneider |

|

FLA |

13.5A |

Control program |

GD-XJ2.0 |

|

Speed |

0-80m/min ( out put) 0-105m/min (paper feeding) |

Servo motor driver |

Schneider |

|

Paper layer |

2-4 layers |

Servo motor |

Schneider |

|

Straw Diameter |

4.3--12mm (out diameter) 3.5--11.3 (inner diameter) |

Schneider |

|

|

Max thickness |

0.6mm-single side |

Schneider |

|

|

Min thickness |

0.2mm-single side |

Relay |

Schneider |

|

Straw length |

100--1400mm Distance between 2 blades |

Signal sensor |

Omron |

|

Cutting method |

8 knife, pneumatic driving |

Encoder |

Omron |

|

Glue method |

Single & double face |

Pneumatic cylinder |

AIRTAC |

|

Length control |

Encoder |

Bearing |

HRB |

|

Speed control |

Servo tracking |

Attached equipment/function |

|

|

Operator |

1 person |

Paper connecting function |

Have |

|

Mandrel fixing |

Screw clamp |

Dust & protection cover |

Have |

|

Synchronism control |

Servo belt |

Winding roller cover |

Have |

|

Winding belt tension control |

Hand wheel |

Cutting knife cover |

Have |

|

Belt angle control |

Hand wheel |

Pull force tension sensor |

Have |

|

Lubrication |

Lubrication grease |

Auto lubrication grease |

Have |

|

Dimension and Weight |

Constant rewinding force |

Have |

|

|

Main part dimension |

3850×1200×1600mm |

Mould Anti-vibration roller |

Have |

|

Land area dimension |

8000×4500×1900mm |

Glue recycle pump |

Have |

|

Winding roller diameter |

215mm |

Cutting system limitation rod |

Have |

|

Winding roller height |

120mm |

Multi-control language |

Have |

|

Weight |

1400 KG |

Stainless steel cover |

Optional |

|

Attached Spare Parts |

|||

|

Paper Straw Mould |

3 sets |

Winding belt |

15 pcs |

|

Cutting blades |

14 pcs |

Tool box |

Have |

|

Air cylinder |

1 pcs |

Thinner pull rod clamp |

2 pcs |

|

Double adhesive tape |

Several for paper roll bracket connecting function |

Metal adhesive glue |

2 bottle |

Compare old model and new model

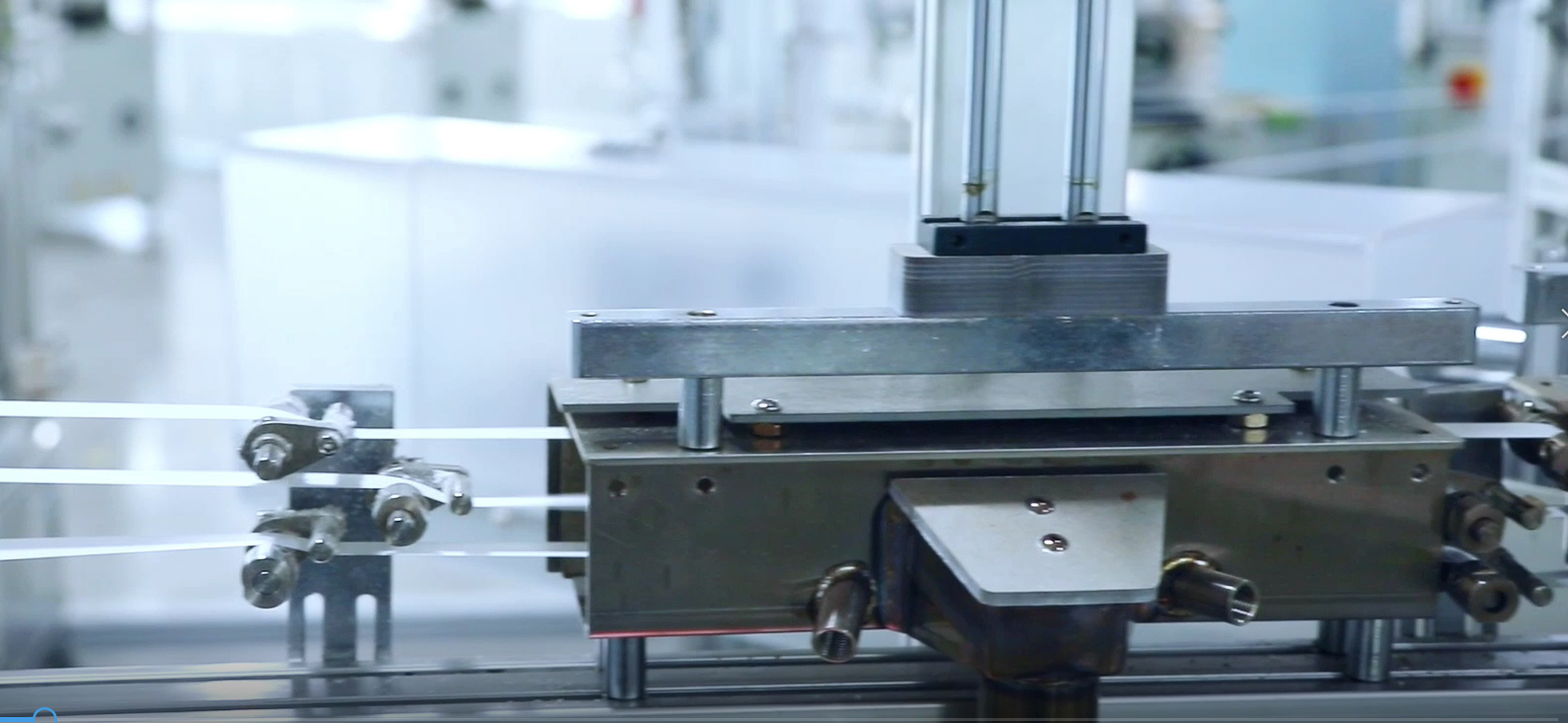

Paper straw making mechanism

|

Cutting blade |

Mould Anti-vibration roller |

Pull rod force sensor |

electric socket and cooling fan |

Cutting blade material:W6Mo5Cr4V2

|

Unit Name |

Description and advantages |

Remark |

|

Winding & control mechanism Multi-knife cutting system

|

Carbon steel; 5 sets servo motor; Dust & protect cover; Language: Chinese, English, Spanish, Polish, Vietnamese, Portuguese and so on; High and low voltage electric equipment separated isolation; Laser cutting and heat treatment to avoid micro shaking; Longer service life; Famous brand electric equipment: Schneider High speed and stable working; Safety labels for protecting method; |

|

|

2 auxiliary servo motor |

Main servo motor |

2 winding roller servo motors |

|

|

|

Paper roll hanging bracket with connecting function

|

Paper roll bracket with connecting function:1. Help paper straw making machine no stop working. 2. Use auto detection: When the paper roll is going to use out, the mechanism will cut the tail ends of old paper roll and connect new paper roll automatically. 3. Smaller dimension, easy delivery and moving to adjust paper feeding angle. 4. Construction simpleness. If paper break, no need to stop to route the paper up and down complicated. 5. Constant unwinding force for the paper rolls, to let paper feeding more smoothly. 6. Our own patent for this connecting mechanism, not copy from others, especially European brands, so no patent problem. 7. Optional choose: 4 layers connecting mechanism. |

|

|

The standard specification is for paper strip width smaller than 20mm. If your method is using paper width bigger thant 20mm, tell me in advance. We need make some parts improve. Other brand paper connector, they call auto feeder. Like this one (right side picture). A huge construction, which have rods to let paper pass through up and down, very complex. Disadvantage of this type:

Because copy Europe brand, may have patent problem in the future. |

One Europa brand design this construction, but each layer paper have its individual connecting unit.

If combine 3 units big connector together, it will crowd and difficult to prepare new paper.

So, we design our own construction with our own patent.

Payment term and after-sale service

Term |

|

Packing: Plastic film package or Wooden box(Optional, need pay) |

|

FOB Price: Sea Freight cost & Insurance are paid by the buyer. |

|

Payment: T/T; 30% down payment, the balance 70% to be paid before shipment. |

|

Lead time: Ordinary model, 40 days. |

|

Training & Service: We suggest that customers take a training for 3-5 days at our factory for installation and operation. How to change paper straw length and diameter, how to judge glue quantity and viscosity. Training at our factory is free. If on-site installation and training, the buyer need pay round tickets cost(from Wenzhou to your factory and return Wenzhou from your factory),food and hotel. What’s more, salary for engineer USD100 per day. |

Other things for consideration

1)Standard specification is 380V, 3 phase, 50Hz. If you need other voltage or 60Hz motor, tell us in advance.

2.)Standard is for making 3 layers paper straws.

4 layer straw is more hardness than 3 layers. I think, for 10-12mm paper straws, it’s better use 4 layers. The material cost also higher.

5 layers is not suitable for paper drinking straws, the cost increased too much.

3) Different diameter need different paper straw mold. The mold includes 3 parts: thinner pull rod, mandrel and cutting mat. So you need tell me which out diameter paper straw that you want to produce.

Main free parts for paper straw making machine

- 14 cutting blades;

- 3 sets paper straw mold;

- 1 air cylinder.

- 15 winding belts;

- 1 cutting blade belts

|

Parts Name |

Picture |

Quantity |

|

Cutting blade |

|

14 pcs/set |

|

Winding belt |

|

15 pcs/set |

|

|

|

1 set of mold including: Thinner pull rod; Mandrel; Cutting mat 3 set mold for free From 5-12 out diameter, choose 3 size. |

|

Air cylinder |

|

1 |

|

Cutting blade belt |

|

1 |

Dryer for paper straw GD-Dryer

|

380V/3 phase/ 50Hz 9.6KW/h Dimension: 2.3*0.7*1.02m 0-10m/min; 120kg Could exchange with collector |

Lifter conveyor

|

Cooperate with other machines, like packing machine, counting machine. 6/8/10mm diameter Let working easier. |

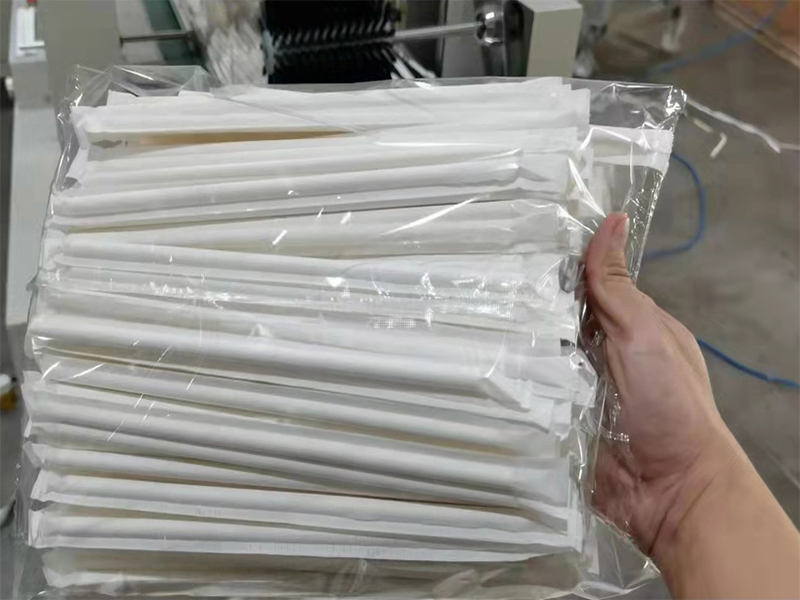

Single Packing&mutlti packing

|

|

Scope of Application

This machine is suitable for packing groups drinking straw in one bag , 50-500pcs can be packed together.

Features

1.Human-Machine Interface in English, adopt touch screen.

2.Bag length can be set in touch screen and cut in one step.

3.Adopt high accuracy photocell tracking systems.

4. Automatic counting function.

5.Single straw packing machine adopt 4 sets servo motor for control.

6. Panasonic sensor for straw and paper detection, no straw feeding or no paper, machine stopped automatically.

Specifications

|

Model |

GD-PL100 (single pack) |

|

|

Drive motor |

3kw |

|

|

Speed |

200~600pcs/minute |

|

|

Seal |

Back side sealing |

|

|

Material |

BOPP or paper material |

|

|

Straw size |

Diameter |

Φ4~Φ12mm |

|

|

Length |

150~280mm |

|

Other size made by order |

||

|

Machine size and weight |

1500 × 800×1750mm 350kg |

|

|

Model |

GD-PL100 (Bulk pack) |

|

Max. film width |

850mm |

|

Packing Speed(Adjustable) |

3-10 bag/min |

|

Film thickness |

0.03-0.06mm |

|

Bag Length |

90–600mm |

|

Bag Width |

80–250mm |

|

Straw quantity |

50-500pcs |

|

Power Supply |

220V , 50/60 Hz , 4 KW, 1 Phase |

|

Machine Size (L x W x H) |

3100 × 1500 x 1550 mm 2000 x 800 x 1200mm |

|

Machine Weight |

750 Kg |

Main electrical parts

GD-PL100 (single pack)

|

Name |

Model |

Quantity |

Brand |

|

Touch screen |

TPC-7062HW |

1 |

Weinview |

|

PLC |

FPOR-C32T |

1 |

Panasonic |

|

Servo motor |

1300W |

1 |

Inovance |

|

Servo motor |

750W |

1 |

Inovance |

|

Servo motor |

400W |

2 |

Inovance |

|

Relay |

HHC68A-2Z |

3 |

Xinling |

|

Air switch |

C20C16 |

1/3 |

CHNT |

|

Power supply |

LRS-50-24 |

1 |

Meanwell |

|

Valve |

|

1 |

Smuk |

|

Photoelectric switch |

CX-441 |

1 |

Panasonic |

GD-PL100 (Bulk pack)

|

Name |

Model |

Quantity |

Brand |

|

Touch screen |

TK6071iQ |

1 |

Weinview |

|

PLC |

FP-X0 M60R |

1 |

Panasonic |

|

Servo motor |

HJ-KS102J |

1 |

Mitsubishi |

|

Relay |

RXM2LB2BD |

7 |

Schneider |

|

Air switch |

C25/C10 |

1/4 |

Schneider |

|

Power supply |

ABL2REM24015H |

1 |

Schneider |

|

Valve |

|

1 Set |

Smuk |

|

Photoelectric switch |

Z3N-TB22 |

1 |

Julong |